Robotics has changed companies’ operations, making industrial processes more efficient and reliable. In today’s increasingly automated world, robotics is no longer only found in factories but can be seen in a wide range of automotive and healthcare industries. We all know that robots are used extensively on assembly lines. But did you know they also play an essential role in many other industries?

This article will look into the six major industries that use robotics the most and explore their applications. We’ll discuss how their utilization has enhanced production efficiency and created new business opportunities worldwide.

Table of Contents

Automotive

The automotive industry is no stranger to the growing use of robotics and automation technologies. From car assembly lines to automated parking systems, robots have become essential for businesses operating in the automotive field. Robotic arms are vital for consistent part production, while driverless cars are becoming increasingly more realistic. Automation is also used for vehicle maintenance, with robotic equipment capable of assisting mechanics in more complex repairs.

For the automotive industry, robotization has proven to be a powerful tool that offers high levels of accuracy and safety. It helps manufacturers save time and money while ensuring quality control standards are maintained across all production processes.

Healthcare

Robotics has revolutionized the way healthcare professionals perform their duties. The healthcare industry has adopted automation from robot-assisted surgery to delivery robots in many of its operations and processes.

Robots are now used for tasks requiring precision, such as delicate surgeries or administering medications. They can also assist with housekeeping and patient transport, using sensors and navigation capabilities to navigate different environments. It helps reduce the human resources needed for those tasks while ensuring safety and accuracy.

Robotic technologies also play a role in medical research by conducting experiments in areas like genetic engineering or drug testing faster than ever before. The possibility of robot-driven exploration and experimentation is proving invaluable for medical advancements worldwide.

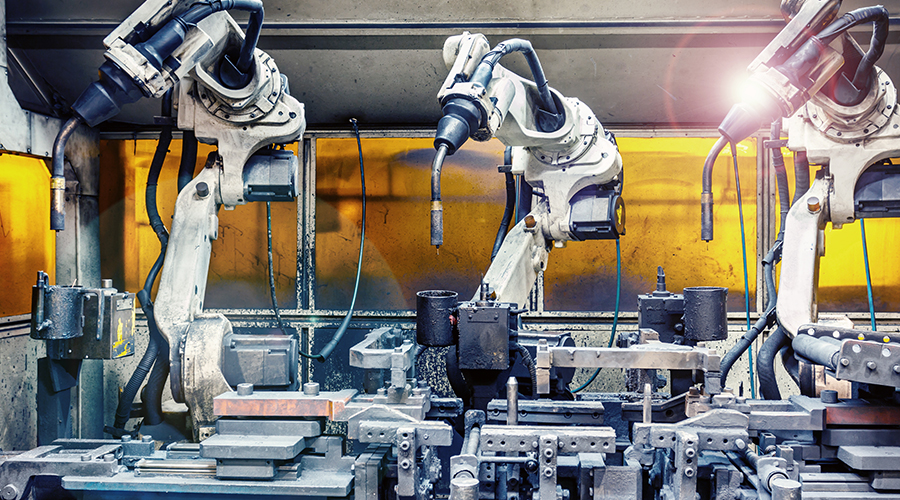

Manufacturing

Industrial robot automation is one of the main drivers of the manufacturing industry, with robot arms and equipment being used for various tasks. From welding and painting to product assembly, robotization has made it easier for manufacturers to produce parts quickly and accurately in large quantities.

Robotics has also been instrumental in making production processes more efficient by reducing human error and minimizing cycle times. It helps companies save time and money while ensuring quality control standards are maintained across all production processes. In addition, robots can be programmed to safely conduct hazardous jobs such as handling corrosive materials or working in extreme temperatures.

Another benefit of robotization in the manufacturing sector is its ability to reduce labor costs and make processes more cost-effective. As robot utilization increases, companies can reduce their reliance on human resources and free up funds for other business areas.

Logistics

Robotics is becoming increasingly prevalent in the logistics industry. From robot-driven delivery to self-driving trucks, automation transforms how goods and services are managed and transported.

In warehouses, robot arms can be used to sort products quickly and accurately across different categories. In contrast, automated guided vehicles (AGVs) move items between different areas within a facility. Automation also enables warehouses to operate 24/7 without any interruptions or downtimes. In addition, robotization helps reduce labor costs by simplifying processes that would otherwise require manual labor.

In logistics, robotization is helping businesses save time and money while ensuring deliveries are made on schedule and with minimum disruptions.

Agriculture

The agricultural industry is turning to robot automation for various tasks, from harvesting crops and managing livestock to monitoring soil conditions. For example, robot-powered tractors can perform most farm activities without any human intervention. Robotics can also be used to pick fruits and vegetables more precisely than ever before.

Robotic systems are also being implemented in greenhouses and other controlled environments to reduce water consumption and increase crop yield with fewer inputs. Automation technologies have proven to be an invaluable tool that helps farmers improve efficiency while ensuring their products meet the highest quality standards.

Robotics in agriculture also helps to reduce food waste by automating the sorting and packaging processes of production. It helps farmers save time and money while ensuring their products reach consumers quickly.

Mining

Robots are playing an increasingly important role in the mining industry. Autonomous robot drills, for example, can bore into mines with greater precision than ever before while reducing safety risks to miners. Robotics is also being used to extract resources with minimal disruption and improved efficiency.

Robotic systems can also be used for surveying underground land or monitoring air quality in mines, helping miners identify potential hazards and prevent accidents. Automation is also improving the accuracy of data collection processes and helping miners reduce labor costs.

In Conclusion

Robot automation is now being used in various industries, from healthcare and manufacturing to logistics and agriculture. By taking advantage of robot-driven systems, businesses can improve efficiency, reduce costs, and maintain quality control standards across all production processes. Robotics is an invaluable tool for improving productivity in many different areas.